Source custom parts for health innovations

-

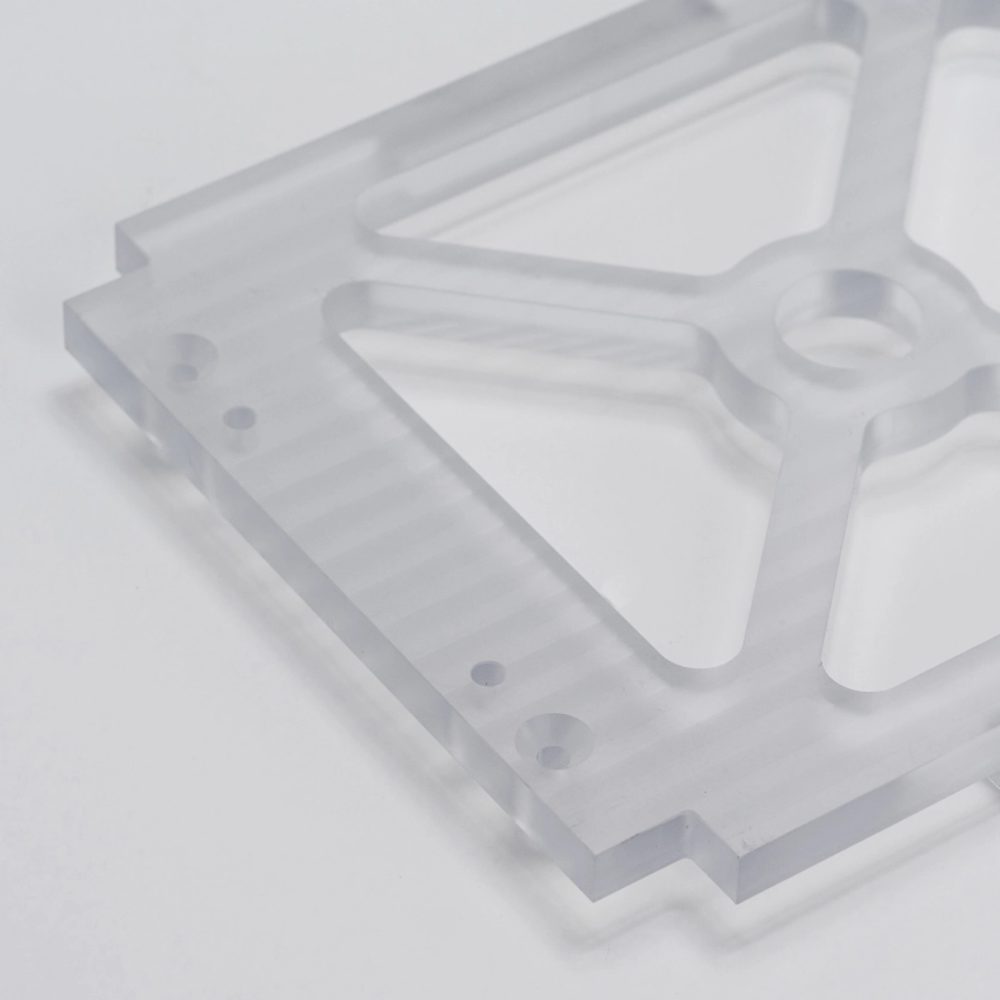

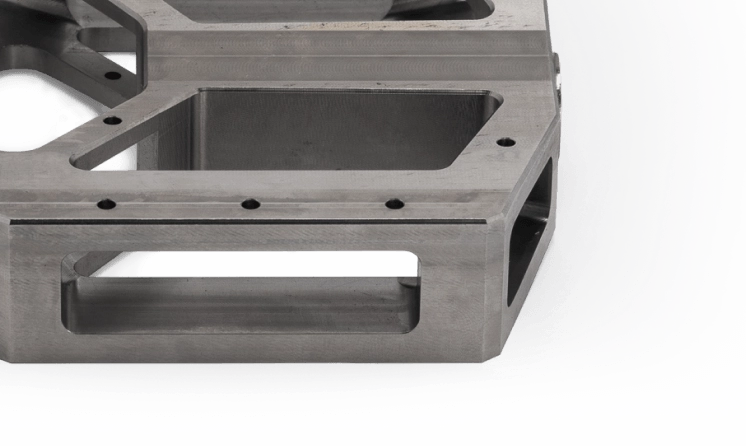

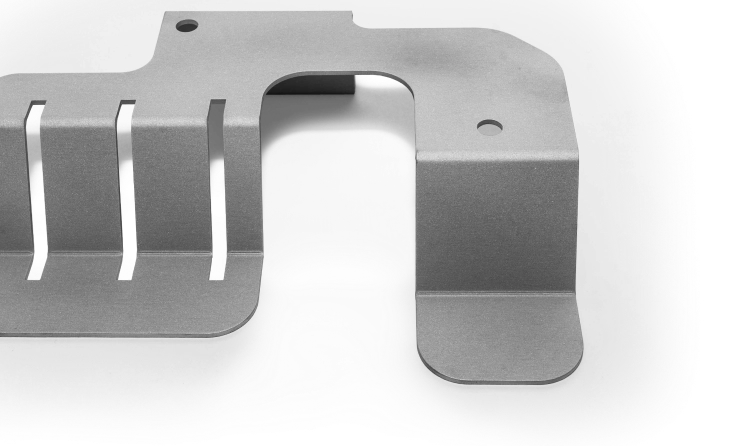

Complex geometries & cosmetic finishes

-

Instant quoting with comprehensive DFM analysis

-

Specialized certifications & quality documentation

Build devices that advance patient care

Protolabs Network is the ideal solution for manufacturing custom parts for diagnostic and medical devices. Our instant quoting platform fast-tracks product development, so you can prototype, innovate, and impact human lives, faster. Whether you’re exploring the next biotech innovation, building devices for medical imaging or stem cell research, or need jigs and fixtures to support them, our network of manufacturing partners has near-limitless production capacity.

Protolabs Network is 9001 certified and our suppliers have specialized certifications.

-

ISO 9001

-

ISO 13485

-

ISO 14001

-

ISO 9100

-

ISO TS16949

-

Medical-grade, FDA-approved materials via Protolabs

Get validation reports to ensure the highest quality and compliance.

-

CMM Inspection Report

-

Full Dimensional Inspections

-

Material Test Reports

-

Material Certificates

-

Certificates of Conformance

-

First Article Inspections

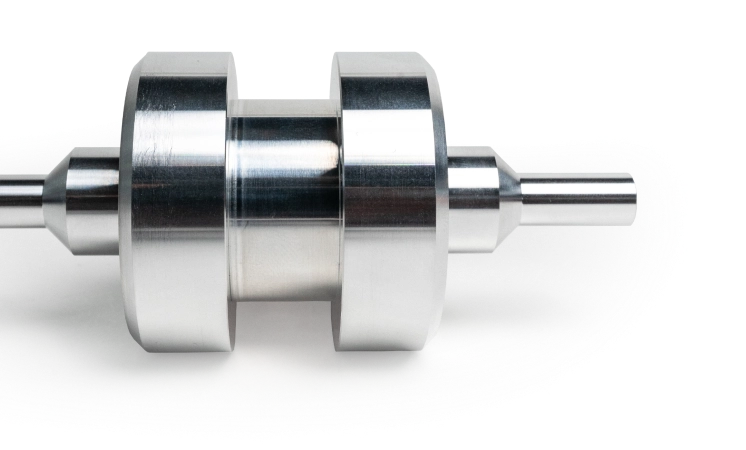

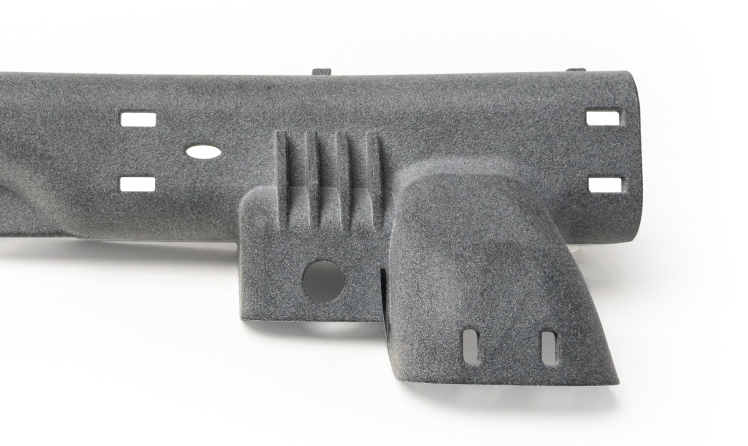

Access a huge range of technologies for making complex custom parts for medical equipment.

-

CNC machining (including 3-axis and 5-axis), milling & turning

-

Injection molding

-

FDM and SLA 3D printing using ABS M30i and Ultem 1010

-

More than 50 metals & plastics

-

Functional & cosmetic post-processing options

Parts in 1 day with Protolabs

Protolabs and its network work together to bring you the world's most comprehensive manufacturing solution. While the network can provide a large breadth of capabilities, Protolabs’ factories offer expedited manufacturing with automated in-house machines for the industry's fastest lead times.

Get quick-turn parts with Protolabs

How medical parts manufacturers use Protolabs Network

Medical manufacturing capabilities

For cost-efficient prototypes and production

-

3-, 4- & 5-axis milling

-

Lead times from 5 business days

Lathes and live tooling ideal for cylindrical parts

-

60+ metals & plastics, including 10+ aluminum & 20+ steel

-

Lead times from 5 business days

FDM, SLA, SLS, MJF

-

± 0.3% with a lower limit of ± 0.3 mm (± 0.012 in)

-

Lead times from 1 business day

Laser cutting, bending, post-processing

-

Tolerances down to ±.004 in (0.1 mm)

-

Lead times from 5 business days

Why healthcare engineers use Protolabs Network

Our ISO 9001-certified quality management system ensures reliable quality across our network.

Materials & surface finishes for medical parts

Through our vetted manufacturing partner network, we provide access to a huge range of durable materials.

Select from more than 30 metal alloys and hundreds of industrial-grade plastics.

-

Steel & stainless steel: 304/304L, 316/316L, 17-4H

-

Titanium: Ti grade 1, 2, 5

-

Aluminum: 6061-T6, 7075-T6, 5083-H111, 2024-T351

-

Brass & copper alloys: C360, copper C110, copper C101

-

Thermoplastics: Polycarbonate (PC), ABS M30i, PLA, PEEK, Ultem 1010, PA 12

-

Commodity polymers: Polyethylene (PE), Polypropylene (PP), PVC

-

Medical-grade, FDA-approved materials available via Protolabs

Improve durability and performance with a selection of finishes

-

Anodizing

-

Polishing

-

Brushing + Electropolishing

-

Smooth machining

-

Electroless nickel plating

-

Chromate Conversion Coating

-

Sandblasting/Shot Peening

-

Part marking/Laser engraving

Gallery of medical parts

How we help medical companies innovate

The Protolabs Network platform is the easiest way to get competitive pricing for comparing order volumes, lead times, materials, tolerances, secondary processes, and more for your projects. Get all final pricing information upfront, including shipping, quality control and customs clearance (when ordering from the US and EU). We prioritize IP protection on the platform and throughout the process to ensure that your designs and models are completely secure. Our platform is equipped with design for manufacturability (DFM) analysis and our mechanical engineers are always on hand to offer guidance to get the most out of Protolabs Network.

To keep your supply chain consistent and sturdy, we adhere to thorough quality control processes and protocols. Our manufacturing partners go through a complete vetting process before joining the network and on-site quality engineers perform frequent audits to ensure they meet the Protolabs Network Standard. Internal teams in Amsterdam and Chicago inspect parts for functionality and cosmetic specifications, and we handle all custom clearance requirements and ensure on-time delivery.

Supply chain resilience is critical, especially when you need parts on a strict schedule and with specific certifications. We offer local and global sourcing to reduce your supply chain risks and provide sourcing solutions to match compliance requirements. Protolabs Network gives you access to the most comprehensive network of industrial 3D printing, CNC machining, injection molding and sheet metal specialists with consistent capacity available for your industrial equipment projects, no matter the scope.

FAQ's

How do we ensure our manufacturing partners are ISO certified?

We do thorough checks of every manufacturing partner (MP) during the initial onboarding process and perform audits on processes and certifications every two years. To source parts from certified MPs, you can indicate these requirements on the platform or contact networksales@protolabs.com. We’ll match your designs with the right supplier.

How does Protolabs Network protect data and intellectual property?

Our platform is secure and encrypted to ensure that customer data and interactions with suppliers are all protected. All digital models and drawings are safely stored on AWS servers, located in Europe. MPs must sign our Manufacturing Partner Agreement as part of their onboarding, which contractually obligates them to keep customer data confidential. Our General Terms of Sale prohibit orders that misappropriate or infringe on copyrights, patents, design rights, trademarks, trade secrets and other IP rights.

What happens if a part doesn’t meet your specifications?

One of the reasons engineers use Protolabs Network is that we take on all the risks for you. If your parts aren’t up to spec, you can file a dispute claim and we’ll remake your components or refund your order. For more detail on how we handle disputes, you can contact our Customer Success Team. At the same time, we complete non-conformity reports for parts that don’t meet all requirements, with follow-up with manufacturers including root cause analysis and rapid corrective actions.

How do I request materials not listed on the site or platform?

If you want to get parts in specialized materials that aren’t listed on our site or platform, you can send a request to your account manager or contact networksales@protolabs.com. Our supplier network has access to a huge range of materials, so most of the time we are able to find a manufacturing partner to fulfill your request.